The system is processing. Please wait a moment!

- Home experience homelift & elevator technical Sharing experiences

What is a Pit? Advantages - Disadvantages of Pitless Elevators

TABLE OF CONTENTS

Pitless elevators mark an important step forward in elevator design and technology. This type of elevator uses components such as electric motors, cables, and screw systems to operate, instead of needing an elevator shaft like traditional elevators. This makes them more suitable for projects with complex structures or ineligible conditions for building elevator pits.

In particular, these elevator lines not only solve space problems but also bring convenience and flexibility in integrating into special architectural projects. By eliminating the need for elevator shafts, they open up many new possibilities for the layout and design of spaces, from classical buildings to modern architectural projects.

The versatility and ease of integration of pitless elevators provide the optimal solution for construction projects that require a high degree of creativity and flexibility. At the same time, they also bring convenience and cost savings to investors and designers during the construction and completion of projects.

What is a pit?

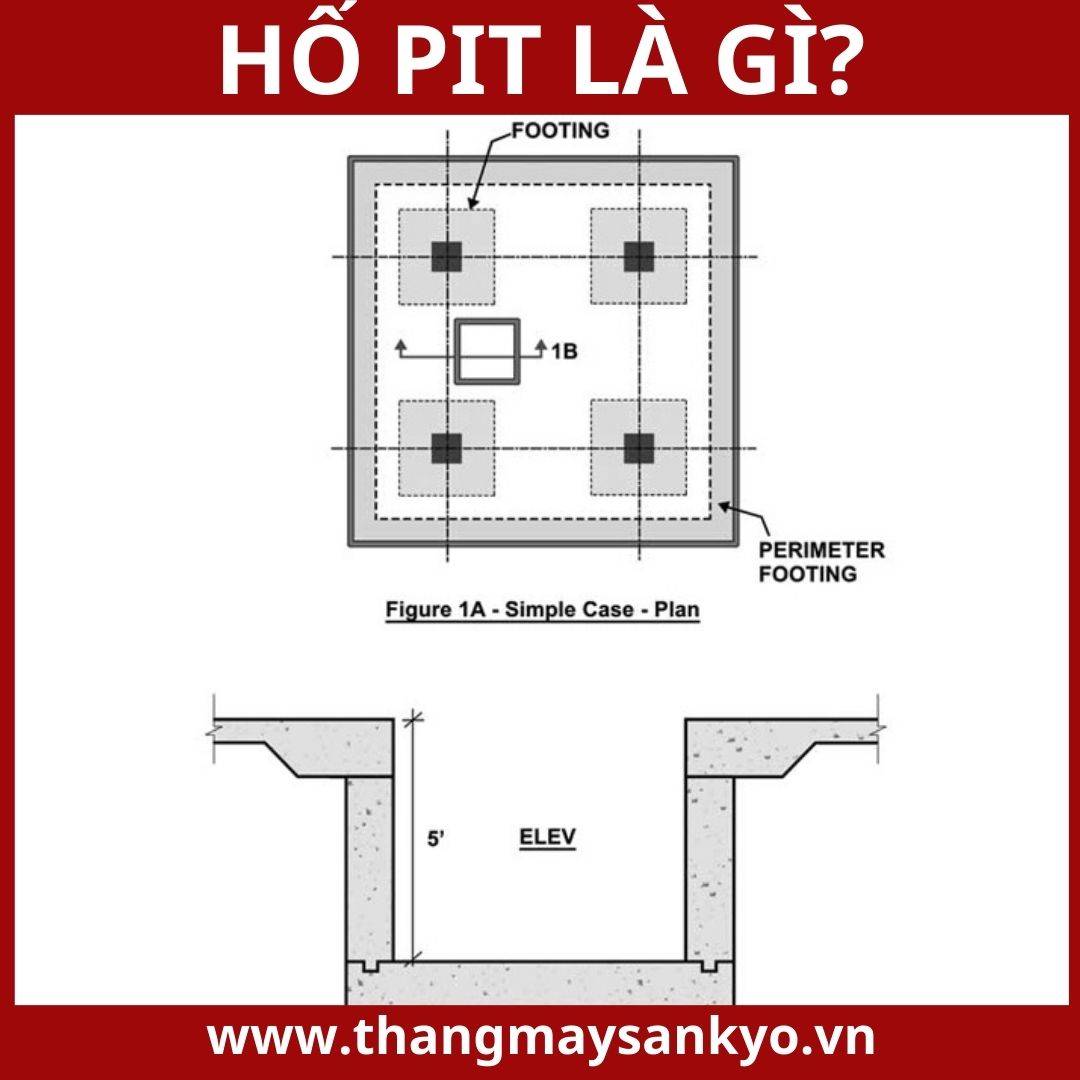

The pit, in technical language, is an integral part of the elevator system and is usually measured from the finished floor of the bottom floor to the bottom of the pit. Normally, the pit is dug under the floor of the lowest floor and is usually at a negative level compared to the floor. The main function of the pit is to create space for the cabin floor or bottom of the cabin to crawl under when the elevator moves to the lowest floor.

For every elevator, the pit is a necessary requirement because it provides space for the lower part of the car when the elevator operates to the lowest floor. In addition, the pit hole is also a location to install other devices such as counterweight damping buffers, cabin damping buffers, limit switches, governor counterweights, and other safety devices.

The design of elevator pits often must comply with specific industry standards and regulations. The depth of the pit can vary depending on the elevator type and technical requirements. Typically, elevators with high operating speeds will require pits with greater depth to ensure safety and performance.

Structure of family elevator pit

In designing the family elevator pit for elevator installation, we need to pay close attention to the structure of the elevator pit to build appropriately. And to do that, you need to pay attention to the following issues:

Pit size : The size of the elevator pit, specifically the internal size, is an important factor. It depends on the type of load and size of the elevator. Usually this size is calculated based on the horizontal size and depth of the pit. The structure of the elevator pit is usually made of reinforced concrete to ensure stability and safety.

Depth of the pit : To install the elevator safely and effectively, the pit needs to be deep enough. Usually, the minimum depth of the pit is regulated at about 450mm for imported elevators, and about 550mm for joint-venture home elevators with reasonable prices.

Pit pit handling in cases of limited space : In cases where the required depth cannot be guaranteed due to underground structures such as water tanks, septic tanks, or foundations, the pit construction method can be applied. pit in a half-submerged, half-surfaced manner. This means creating a part of the pit above the ground or adding some steps in front of the elevator door to ensure sufficient depth.

Thereby, careful attention and handling of factors related to pit structure will help ensure the safety and efficiency of the home elevator system.

SEE MORE OTHER PRODUCTS:

What is a pitless elevator?

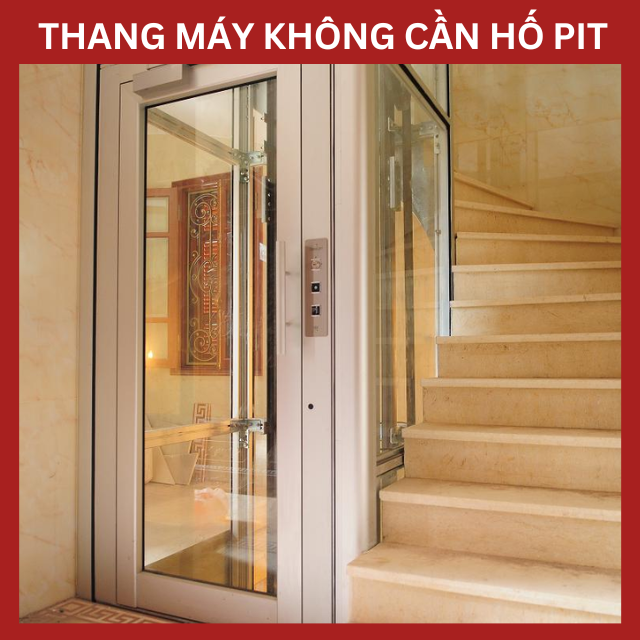

Pitless elevators are a convenient and flexible solution for family homes, helping to reduce the disadvantages of traditional pits. This type of elevator is designed to have a lower pit or even no pit, allowing the entire elevator equipment to be installed on the floor of the house without having to dig a deep pit. This brings convenience and saves space for installing elevators in family home spaces. Pitless elevators are often integrated with advanced technologies and designs, helping to optimize the performance and flexibility of elevator systems in residential spaces.

.jpg)

Advantages of pitless elevators when used in housing

Save space

Saving space is one of the outstanding advantages of pitless elevators, because there is no need to reserve part of the floor area for a pit. This not only helps optimize floor area, but also opens up more creative possibilities in designing space inside the building.

Instead of having to dig or prepare an underground space for a pit, pitless elevators can be installed directly on the floor. This saves significant space and allows floor space to be used more efficiently for other purposes, such as storage or living space.

Besides saving space, eliminating the need for a pit also opens up opportunities for more creative designs within the building. This not only creates a better user experience, but also enhances the aesthetics of the building, while promoting creativity in the design and construction process.

Easy installation

The process of installing pitless elevators becomes significantly easier thanks to the elimination of underground excavation and environmental remediation work. This step not only helps minimize the time and effort required to prepare the installation environment, but also reduces the risk of damage to surrounding structures and the environment.

Not having to carry out underground excavation and environmental remediation works not only reduces the time and effort required to prepare the installation environment, but also reduces the risk of damage to the structure. surrounding structure and environment. This brings significant cost benefits and increased efficiency during project implementation. In particular, the flexibility of this installation process is also suitable for home renovation projects, where performing excavation and environmental remediation works can be limited and difficult.

SEE MORE OTHER PRODUCTS:

Lower costs

Not needing to dig pits and treat the underground environment brings significant cost benefits. By eliminating these steps, not only do you reduce the costs of materials and labor involved, but you also reduce the risk of unexpected costs arising from unexpected problems while working with the soil environment. .

Minimizing the material and labor costs associated with pit excavation and underground environmental remediation not only reduces initial costs but also reduces the risk of unexpected costs arising from unexpected problems. desired in the process of working with the land environment. This helps projects complete at lower costs and with greater efficiency, while providing significant financial benefits.

Increase safety

Eliminating pits in elevator design brings significant safety benefits. Because there is no pit, the risk of falling into the pit or falling from a height is completely eliminated. The pitless elevator system is designed with the goal of ensuring maximum safety for users, especially sensitive groups such as children and the elderly.

Eliminating pits in elevator design not only minimizes the risk of falling into pits or falling from heights but also creates a safer environment for users. Pitless elevator systems are specifically designed to ensure maximum safety, especially for sensitive groups such as children and the elderly.

Disadvantages of elevators without pits when used in housing

Besides the advantages, using a home elevator without a pit also has certain disadvantages such as:

Limited weight and size

Although eliminating the pit brings the convenience of saving space, it also comes with limitations on the load capacity and size of the elevator. Specifically, elevators that do not require pits often have limitations in load capacity and size compared to traditional elevators.

This may affect the usability and performance of the elevator under special conditions or specific job requirements. Because pits do not exist, these elevator systems often have to be limited in terms of load capacity and size, especially in situations that require more endurance and strength. This can reduce the flexibility and applicability of the elevator in some special cases.

Speed limit

Another limitation of elevators that do not require a pit is the possibility of lower transit speeds compared to other types of elevators. Without support from the pits, achieving higher speeds can be fraught with technical and safety limitations.

Lack of pits can limit an elevator's ability to improve speed, as systems without pits are typically not designed to achieve high transport speeds. This can reduce the flexibility in choosing the right elevator for the specific needs of each project or usage environment. Speed restrictions can affect elevator performance and usability in some special situations, especially in projects requiring high speed and performance

SEE MORE OTHER PRODUCTS:

Design limitations

The absence of a pit can limit the design and special features of the elevator. Because there is no underground space to install the mechanical parts of the elevator, this can reduce the flexibility to create unique designs or special features for the elevator.

Lack of pits can reduce the ability to customize and personalize an elevator, as there is no underground space to accommodate mechanical parts and equipment. This can limit the ability to create unique designs or special features, such as elevators with transparent windows, special cabin designs, or enhanced security features. Designers and engineers must work with tighter space constraints and more demanding technical requirements when developing design solutions for pitless elevators.

Types of home elevators without pits or low pits

Currently, the market offers a wide range of pitless home elevators, each with features suitable for each project and the specific needs of the user. Here are two common types used today:

Hydraulic elevator:

Suitable for houses from 2 to 6 floors.

Load capacity under 630kg.

Moving speed is usually from 0.15 to 0.3m/s.

Pit depth usually ranges from 100 to 200mm.

Screw elevator:

Suitable for houses from 2 to 5 floors.

Load capacity under 500kg.

Moving speed is usually at 0.15m/s.

Pit depth is usually only about 60mm.

These types of elevators are designed to accommodate the transportation needs and available space in residential homes without the need for a pit. Technical parameters are adjusted to suit the specific requirements and conditions of each project, helping to optimize the performance and utility of the elevator in the home environment.

In summary, from the above information, we see the important role of the pit in the process of building and operating the elevator, ensuring the safety and performance of the system. However, it is impossible to deny the advantages of using elevators without pits, such as the ability to save construction costs and suitability for certain space conditions.

Whether you choose an elevator with a pit or not, the most important thing is to clearly understand your specific needs and requirements to make the best decision. Thoroughly learning about the pros and cons of each type of elevator will help you choose the most suitable choice for your project, while ensuring safety and efficiency in using home elevators.

SEE MORE OTHER PRODUCTS:

.png)

.png)

.png)