The system is processing. Please wait a moment!

- Home Sankyo Elevator Products FOOD ELEVATOR - FOOD WINCH

FOOD ELEVATOR - FOOD WINCH

Sorted by:

TABLE OF CONTENTS

- Features of freight elevators

- Applications of freight elevators

- The difference between freight elevators and passenger elevators

- Popular types of freight elevators

- Structure and working principle of freight elevator

- Safety features of freight elevators

- Classification of freight elevators

- Specifications and dimensions of common freight elevators

- How much is a freight elevator?

In today's era, freight elevators , also known as freight elevators, have become an essential part of the transportation system, contributing significantly to optimizing production and operation processes in high-rise buildings, factories and industrial facilities. Specially designed to serve the movement of goods, freight elevators help eliminate the difficulties in transporting heavy, bulky materials that humans can hardly handle effectively. The use of freight elevators not only increases productivity but also saves time and labor costs, bringing outstanding efficiency in the production and business process. Businesses today prioritize choosing freight elevators as an optimal solution for internal transportation systems, helping operations become smoother, safer and more efficient.

SEE MORE ARTICLES

In this article, Hoang Sa Viet Elevator will explore with you in detail about freight elevator technology - a modern transportation solution that plays an important role in daily life and in modern industry. From helping to move goods easily in high-rise buildings to supporting fast transportation in factories and industrial facilities, freight elevator technology has become an indispensable factor to ensure efficiency, safety and labor productivity. We will share with you the outstanding benefits that this type of elevator brings, along with diverse applications in different fields, helping you better understand the importance and high applicability of freight elevators in all production and business activities today.!

SEE MORE PRODUCTS:

FEATURES OF FREIGHT ELEVATORS

In terms of design, the freight elevator is specially manufactured with a spacious and sturdy cabin to meet the needs of transporting heavy goods. The large cabin size along with a flat floor makes moving the cart easy, convenient, and without obstacles when entering and exiting. This design not only optimizes the space inside the cabin but also ensures safety during the transportation process, allowing the elevator to withstand large loads while still operating stably. This is an ideal choice for factories, warehouses and production facilities that need an effective cargo handling solution, contributing to optimizing the operating process.

The operation of the freight elevator is optimized to ensure smooth movement, minimize vibration, thereby protecting the quality of goods during transportation. This is an especially important factor for fragile or easily deformed goods, requiring tight and safe packaging. The freight elevator system is designed to operate continuously and stably, ensuring effective service for the production process in factories or workshops. Thanks to that, the process of transporting goods becomes fast, safe and contributes to improving production efficiency, meeting the requirements of modern industrial environments.

The control system of the freight elevator is equipped with advanced technology, providing high efficiency and long-term durability. For freight elevators with small and medium-sized doors, the control system uses voltage conversion and VVVF inverter technology, which helps to adjust the speed and ensure flexible door opening, saving energy. For freight elevators with large doors, the DC drive system is used to increase capacity and durability, meeting the requirements of continuous and efficient operation.

The freight elevator motor control system applies the stepless speed control method through frequency and voltage conversion, which helps reduce energy consumption during operation. This not only ensures that the elevator stops at the floors accurately, but also optimizes the transportation of goods, creating favorable conditions when combined with forklifts. As a result, the freight elevator becomes an effective and sustainable solution for businesses, meeting the needs of transporting goods in modern industrial environments.

SEE MORE ARTICLES

APPLICATIONS OF FREIGHT ELEVATORS

Below are some important applications of freight elevators :

-

Freight elevators in the food industry: In the food industry, freight elevators play an important role in supporting the efficient and safe transportation of goods. Food products, especially those that require refrigeration, can be easily transported from cold storage to other floors of the store or manufacturing plant without disrupting the supply chain. The use of freight elevators not only saves time in moving goods, but also ensures that products are kept at ideal temperature conditions throughout the transportation process. This is important in maintaining the quality, freshness of food and meeting hygiene and safety standards.

-

Freight elevators in logistics: In the logistics industry, freight elevators play an essential role in optimizing workflow and transporting goods in distribution centers. With the need for fast and safe movement, freight elevators help transport large quantities of goods from one floor to another, minimizing time and effort. Thanks to the ability to operate continuously and stably, freight elevators ensure that goods are transferred quickly, contributing to speeding up the order processing process. This not only increases work efficiency but also helps businesses meet the growing transportation needs in the logistics sector. The flexibility and efficiency of freight elevators help distribution centers better manage the flow of goods, reduce congestion and optimize storage space.

-

Freight elevators in manufacturing and construction: In the manufacturing and construction industries, freight elevators play an important role in transporting materials, machinery and components between floors efficiently and safely. Specially designed to withstand heavy loads, freight elevators help factories and construction sites quickly transport bulky and heavy materials, from raw materials to specialized production equipment. Thanks to this system, workers not only save time and effort but also ensure smooth operations, avoiding unwanted interruptions. Freight elevators help businesses optimize workflow, improve production efficiency and minimize risks in the process of transporting heavy or fragile items, contributing to the overall success of manufacturing and construction projects.

In short, freight elevators play an essential role in many different industrial sectors, from manufacturing to construction, food and logistics. With the ability to transport goods and heavy materials safely and efficiently, freight elevators help optimize the transportation process, saving businesses significant time and effort. This elevator system not only ensures continuity and stability in production but also contributes to improving work performance, enhancing the overall efficiency of production and service activities. The integration of freight elevators has become an important factor, meeting the increasing demand for speed and efficiency in modern supply chains, contributing to more sustainable business development.

THE DIFFERENCE BETWEEN FREIGHT ELEVATORS AND PASSENGER ELEVATORS

To get an overview of the differences between freight elevators and passenger elevators , let's find out more details about the important differences between them with Hoang Sa Viet Elevator .

|

Freight elevator |

Passenger elevator |

|

|

Structure |

Simpler than passenger elevators, without human safety devices. |

Including cabin, tractor, counterweight and human safety equipment. |

|

Load |

100 - 5000kg |

300 - 2000kg |

|

Elevator pit (pit) |

|

Pit size is usually 1000mm deep or more |

|

Speed |

From 30m/min - 60m/min, because of carrying goods, the allowed speed is quite low. |

From 60m/min - 150m/min depending on the design of the number of floors of the project |

|

Engine |

|

Engines are manufactured by major manufacturers such as: Fuji, Mitsubishi, Montanari, Otis, Thyssenkrupp,... |

|

Classify |

|

There are two main lines: joint venture passenger elevators and imported passenger elevators. |

|

Price |

Much cheaper than other elevators. |

Depending on the engine type, design, number of floors, the price will be different. |

SEE MORE PRODUCTS:

POPULAR TYPES OF FREIGHT ELEVATORS

Currently, there are many different types of freight elevators on the market , including two main lines:

Freight elevator combined with passenger transport

The freight elevator combined with the passenger elevator is an optimal solution for projects with special requirements for transporting heavy loads and meeting the needs of human movement. This elevator line is designed with strong load capacity, making the transportation of large goods easy and fast, while still ensuring safety and convenience for users.

In particular, this type of elevator is ideal for factories, warehouses, office buildings or commercial centers, where the transportation of goods and the movement of employees or customers take place in parallel. Freight elevators combined with people transportation not only optimize space and time but also create a comfortable and safe working environment, minimizing risks and incidents during the movement process. With these outstanding features, this type of elevator is increasingly popular and widely used in many industries, from manufacturing to commerce, helping to increase operational efficiency and improve work quality.

Freight elevator without people

Freight elevators without people are an efficient and safe transportation solution, especially widely used in warehouses, factories, industrial zones, and environments that require the transportation of heavy loads without the need for service to the user. This type of elevator is specifically designed to transport goods only, helping to optimize space and improve work efficiency in production, storage and distribution processes.

With the ability to transport large and bulky goods, the passenger-free freight elevator saves time and effort in moving goods between floors, while minimizing risks when moving goods by hand or cart. Separating the functions of transporting people and goods helps this elevator operate more efficiently, reducing the load on the system and ensuring greater stability and safety during operation.

SEE MORE ARTICLES

Thanks to its independent cargo transport feature, the unaccompanied freight elevator is the ideal choice for industrial and commercial facilities that need to transport materials, goods, machinery or manufactured products in large quantities, contributing to improving productivity and work efficiency.

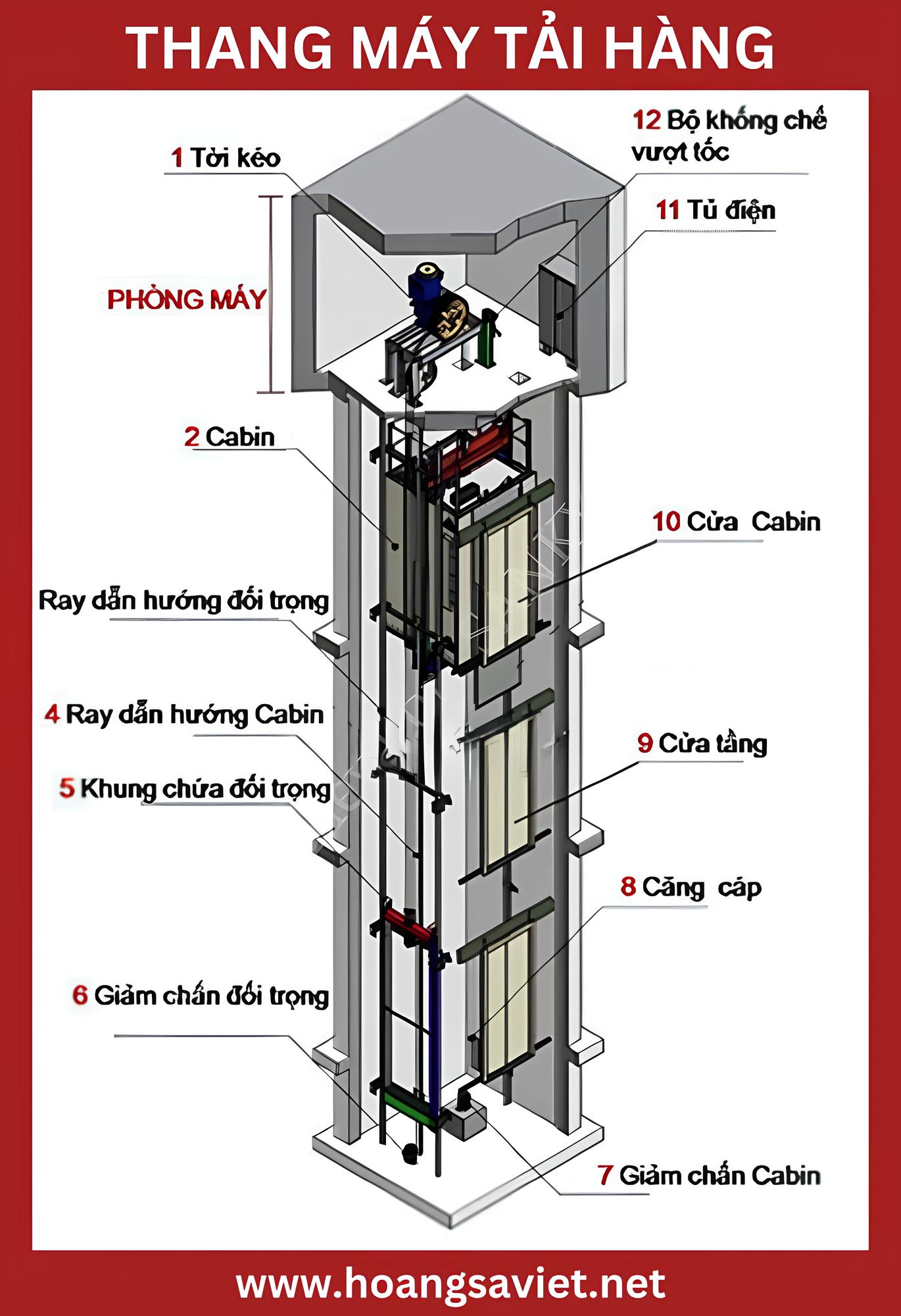

STRUCTURE AND WORKING PRINCIPLE OF FREIGHT ELEVATOR

Freight elevators play a vital role in the infrastructure of many industries, especially in manufacturing, warehousing, and distribution environments. With the task of transporting goods and materials between floors, freight elevators help optimize workflows, saving time and effort in moving products, machinery, and heavy materials. To serve many purposes and specific requirements of each field, freight elevators have a very diverse structure and operating principle, from simple elevators for low-rise buildings to complex systems for high-rise industrial parks.

About structure

-

Cabin and door:

The cabin and door of the freight elevator are specially designed to meet the needs of transporting large and heavy goods, completely different from the elevator for people. With a spacious and sturdy cabin, the freight elevator can accommodate bulky or heavy goods, from industrial machinery to building materials or finished products. To ensure the convenience and efficiency of transporting goods, the door of the freight elevator is also designed to be large and sturdy. The door of the freight elevator can be opened wide, allowing easy loading and unloading of goods without any obstacles, thereby saving time and effort in the process of loading and unloading goods.

In addition, the doors of freight elevators are often equipped with modern control systems, which help open the doors quickly and safely, ensuring that the transportation process takes place smoothly. This is very important for working environments that require high speed and efficiency, such as warehouses, factories, or industrial zones. The cabin and doors of freight elevators are designed to withstand large loads, ensuring safety for both goods and users, while providing convenience.

-

Lifting system:

The lifting system of a freight elevator plays an important role in controlling and implementing the process of moving goods from one floor to another safely and efficiently. Freight elevators are often equipped with powerful lifting systems, including cables, chains or clutches, each with its own advantages, depending on the specific requirements and applications of the elevator. Cables are one of the most common means of lifting systems, used to pull and lift goods with large load capacity and smooth operation. Chains are also a popular choice, especially for freight elevators that require durable and stable operation in harsh working environments, such as warehouses and factories.

In addition, the clutch in the lifting system of the freight elevator is responsible for controlling the movement of the cabin accurately and safely, helping the lifting process to take place smoothly without slipping or having problems. Depending on the design and work requirements, these parts will be optimized to ensure stable operation, especially in industrial environments and applications that require the transportation of large volumes of goods. This lifting system not only makes it convenient to transport goods between floors but also contributes to improving work efficiency, saving time and manpower. In addition, it also ensures absolute safety for goods and users throughout the operation.

-

Control system:

The control system of the freight elevator plays a very important role in ensuring safety, performance and stability during operation. Equipped with intelligent control technology, this system helps to accurately manage all impacts related to the transportation of goods, from moving the cabin to activities such as opening doors and stopping at floors. The intelligent control system not only helps to monitor the operation of the freight elevator but also gives warnings when there is a problem, helping to prevent unwanted impacts that may occur such as overloading, jamming doors or malfunctioning in the lifting system.

SEE MORE ARTICLES

This is especially important in industrial and warehouse environments, where goods can be large, heavy and require continuous operation throughout a long working day. Modern control systems help freight elevators operate smoothly, accurately and efficiently, while ensuring that every operation is carried out correctly and to the highest safety standards. Features such as stepless speed control, precise stopping at each floor and overload protection are essential elements of freight elevator control systems, helping to optimize the transportation of goods, increase the durability and lifespan of the equipment.

The freight elevator control system can also be connected to remote monitoring systems, allowing managers to monitor and check the elevator's operating status anytime, anywhere. This not only helps detect problems in time but also supports maintenance and repair work, thereby extending the life of the elevator and minimizing additional costs. Thanks to the intelligence and flexibility of the control system, the freight elevator not only meets the requirements of efficient freight transportation but also ensures a safe and convenient working environment.

About working principle

Freight elevators operate on a complex electromechanical principle, combining motors, cable systems and mechanical mechanisms to perform the process of lifting and lowering goods accurately and efficiently. When the freight elevator is activated, the motor will start working, providing power to the entire system. At this time, the filter system or drive motor will be connected to the elevator, and the pulleys will start rotating. The rotation of this pulley causes the cable connected to the elevator cabin to move, pulling the cabin in a pre-set direction, helping to smoothly move goods from one floor up or down.

When the freight elevator needs to move up or down, the elevator's mechanical system will change the direction of the motor. This helps the cable system move in the opposite direction, performing the process of lifting or lowering the goods accurately. This process is controlled flexibly and automatically, ensuring that the cabin will move to the correct position and stop accurately at each floor without causing problems or affecting the quality of the goods.

To achieve optimal performance and durability, freight elevators use a series of mechanical and electronic components such as pulleys, cables, clutches, and speed control systems. This system not only helps ensure the stable operation of freight elevators, but also helps control the stopping and starting process, avoiding collisions or malfunctions during use. Thanks to this working principle, freight elevators not only help optimize the transportation of goods in high-rise buildings, factories, or industrial parks, but also enhance the safety and efficiency of the production and operation of industrial facilities.

SEE MORE PRODUCTS:

SAFETY FEATURES OF FREIGHT ELEVATORS

Below, we would like to introduce the specific safety features of the freight elevator line :

Mechanical door locking system:

Freight elevators are equipped with a special mechanical door locking system, which plays an important role in ensuring the safety of users and goods during operation. This system operates on an automatic principle, helping to control the opening of the elevator door only when the cabin has moved to the desired floor. Specifically, when the elevator is not at the correct floor position, the door will not open, which prevents users from accessing the elevator safely. Thanks to this feature, freight elevators help avoid dangerous incidents such as users accidentally opening the door when the cabin has not stopped at the correct position, thereby minimizing possible accidents.

SEE MORE ARTICLES

The mechanical door locking system also helps protect the goods inside the cabin, ensuring that they are not affected by unwanted impacts during transportation. This design not only enhances operational safety but also creates confidence for users when transporting valuable or fragile goods. In addition, this door locking system also helps the elevator operate more stably and efficiently, ensuring that the goods transportation process goes smoothly without encountering door problems or other obstacles.

Door safety:

The door safety system of the freight elevator is an important part in protecting users and goods during operation. Freight elevators are equipped with advanced safety features that stop the elevator if the door is not properly closed. This ensures that the elevator will not move until the door is completely closed, avoiding the situation of the door opening while the elevator is operating. In addition, the system also integrates a feature to detect sudden door opening during the operation of the elevator. If the door is opened unexpectedly, the elevator will immediately stop and stop operating to ensure that no dangerous incidents occur.

This feature is extremely important in maintaining the safety of both users and goods, especially when the freight elevator is transporting heavy or fragile materials. By ensuring that the door is always closed and stops operating immediately when there is an abnormality, the door safety system helps to minimize risks and bring peace of mind to the operator and related subjects. In addition, this feature also contributes to improving the efficiency of the freight elevator , helping the transportation of goods to take place continuously without interruption or encountering unfortunate incidents.

SEE MORE PRODUCTS:

Emergency lighting:

Emergency lighting is an important feature in the safety system of freight elevators, designed to ensure absolute safety for users in the event of an incident. This light is usually installed under the cabin or on the roof of the cabin, with the function of illuminating and warning users to recognize and stay away from the area where the elevator is operating. When the freight elevator is operating, emergency lighting helps users easily identify and determine the operating status of the elevator, thereby avoiding unwanted situations such as approaching the elevator while it is moving.

In addition, emergency lighting also plays an important role in power outages or when an incident occurs, helping users easily recognize the location of the elevator and surrounding areas in low light conditions. In particular, the installation of emergency lighting helps improve the overall safety of freight elevators, ensuring that operations are carried out in absolute safety conditions. This feature not only helps operators be more aware of the status of the elevator, but also contributes to the protection of property and goods when the elevator is operating in industrial environments or areas with high traffic.

Overload notification system:

The overload warning system is an extremely important and necessary feature for freight elevators, helping to ensure absolute safety during operation. When freight elevators are used to transport goods, load control is a decisive factor for the stability and durability of the equipment. The overload warning system operates when the weight of the goods exceeds the allowable limit, helping to prevent the elevator from being overloaded, thereby protecting both the user and the mechanical equipment of the elevator.

When the load exceeds the safe level, the system will activate the alarm, emitting a continuous sound signal to notify the operator or user that the elevator is overloaded. In this case, the elevator will automatically stop operating and not allow further operation until the load is reduced to a safe level. This helps prevent problems such as motor failure, minimize the risk of accidents and ensure that the elevator always operates in safe conditions.

SEE MORE ARTICLES

The overload warning system not only helps protect the equipment, but is also an important factor in maintaining the performance and durability of the freight elevator. It helps users easily recognize the elevator status and take timely corrective measures. The installation of this system also helps improve the operating process, minimize unnecessary damage incidents and prolong the life of the equipment.

Lighting and ventilation system:

The lighting and ventilation systems in freight elevators play an important role in maintaining a safe and comfortable operating environment for users, while also helping to save energy effectively. Specifically, the lighting system is only activated when the elevator stops at a floor and the door is open, providing enough light for the transportation of goods, while avoiding unnecessary energy consumption when the elevator is not in operation. Similarly, the ventilation fan only operates when the elevator door is open, facilitating air circulation in the cabin, helping to maintain ventilation and limit heat accumulation, especially during the transportation of large volumes of goods or when the elevator is in operation for a long time.

SEE MORE PRODUCTS:

One of the highlights of this lighting and ventilation system is the ability to automatically stop when the elevator is not in a stop position at the floor or the door is not open. This not only helps to minimize the amount of electricity consumed when the elevator is not in operation, but also contributes to protecting the environment, reducing operating costs for facilities using freight elevators for a long time. By optimizing energy use, the lighting and ventilation system helps businesses and companies save on electricity costs while still ensuring safety and comfort for users during elevator operation.

Automatic rescue system when power is cut off:

The automatic rescue system in case of power failure is an important feature that helps ensure safety and convenience during the use of freight elevators. When a power failure occurs, this system will automatically activate and operate, bringing goods and accompanying people (if any) to the nearest floor. This helps users to continue using the elevator safely and conveniently when the power is restored. Designing such an automatic rescue system not only helps to minimize disruptions in the transportation of goods but also brings peace of mind to users, especially in environments with high elevator usage frequency such as factories, warehouses, or production facilities.

In addition, if the elevator is equipped with an automatic door, the rescue system will also activate the door opening function and keep the door open until the power is restored. This makes it easy for users to get in and out of the elevator without any problems when the elevator is not operating. Ensuring the continuous and safe operation of the elevator even in the event of a power outage is an important factor in protecting goods and optimizing work processes in industrial facilities. The automatic rescue system in case of power failure not only enhances safety but also improves the efficiency of elevator use in all conditions, ensuring that the facility's operations are not interrupted.

SEE MORE ARTICLES

External communication system in case of incident:

The external communication system in case of an incident is an extremely important factor to ensure the safety of the users of the freight elevator in case of an incident. This system is equipped with a telephone or a fixed notification device, placed in a position that is easy to recognize and access when an incident occurs. When the elevator has an incident or any emergency situation, the alarm will ring and the user can immediately use the communication device to report the current situation.

This communication system allows users to contact management or technical services directly for timely assistance, ensuring that problems are dealt with quickly and efficiently. This not only helps to resolve emergency situations, but also gives users peace of mind, knowing that they can quickly receive support if needed.

By equipping the freight elevator with an external communication system, it not only enhances safety but also optimizes maintenance and troubleshooting processes, minimizing downtime and ensuring continuous operation. This system is an indispensable part in ensuring the elevator always operates stably and safely throughout its use, especially in industrial environments, warehouses or production areas with high frequency of use.

Mechanical brake and anti-overspeed system:

The mechanical braking and overspeed protection system is an extremely important safety feature in freight elevators, especially when the elevator is traveling at a speed exceeding the permitted level. When the elevator is operating, it is possible that the elevator will run too fast or lose control, and this can lead to serious risks if the appropriate safety system is not in place. To prevent this situation, the Governor system is equipped to regulate the elevator speed and protect users from dangerous situations.

SEE MORE ARTICLES

When the elevator runs at a speed exceeding the safety limit, the Governor system will automatically activate, pressing the mechanical brake on the elevator rail . This helps to stop the movement of the cabin quickly and safely, preventing the cabin from falling freely, protecting goods and users from unwanted accidents. This feature is especially useful when the freight elevator is accompanied by people, helping to ensure that safety requirements are always met.

The mechanical braking and overspeed protection system not only helps the elevator operate stably but is also an important factor in improving the reliability and efficiency of freight elevators in industrial environments, warehouses and production areas. This is an indispensable additional feature, especially for elevators with large capacity and requiring safe movement of both people and goods.

Error display function:

The fault display function in freight elevators is an important feature that helps ensure the efficient and safe operation of the system. When the elevator has a problem or technical failure, this system will automatically detect and display errors on the control panels, PLC (Programmable Logic Controller) system and the floor display screen, helping technical staff easily identify the problem.

Having an error display function will help technicians quickly and accurately determine the cause of the problem, thereby taking timely corrective measures without interrupting the cargo transportation process. These error messages are usually displayed in the form of error codes or detailed warnings about the problem that is occurring, such as electrical or mechanical system errors or problems with the control system.

The fault display function not only helps to optimize the maintenance and repair process, but also plays an important role in enhancing the safety of users. When a problem occurs, management staff can be quickly notified, minimizing the risk of accidents and elevator downtime. Thanks to this feature, the freight elevator not only operates stably but also meets high safety and performance standards in all working conditions.

SEE MORE PRODUCTS:

Engine protection function:

Motor protection is an essential feature in freight elevators to ensure the longevity and safety of the motor system. To prevent overheating and minimize the risk of fire, the system is designed to automatically stop the elevator after the motor has been running for a certain period of time, usually about 10 seconds. This is especially important when freight elevators are continuously operating in industrial environments, where the constant demands of transporting goods can put a lot of stress on the motor.

The temporary motor stop not only protects the components from rapid wear and tear, but also prevents motor overheating, one of the main causes of unexpected failures and incidents in elevator systems . In addition, thanks to this automatic feature, the operator does not need to constantly monitor the motor, minimizing the risk of damage and increasing the operational efficiency of the entire system.

The motor protection function plays an important role in maintaining stability, helping the freight elevator operate durably and safely for a long time, meeting maximum usage needs without affecting the life of the equipment.

Other safety systems:

In addition to the key safety features, freight elevators are also equipped with many other protection systems to ensure safety and efficiency during operation. One of them is the floor stop bell system, which allows clear notification to users whenever the elevator stops at the desired floor, making transportation and unloading easier and more convenient. In addition, the system also integrates phase loss and reverse phase protection functions, ensuring that the power supply to the elevator always operates properly and stably. These features play an important role in protecting the elevator's motor and electronic components , preventing potential problems that could affect the operation of the equipment. Thanks to these additional safety systems, freight elevators not only ensure high performance but also give users more peace of mind when operating in complex industrial environments.

Safety features on freight elevators play a very important role in protecting users as well as ensuring the safety of goods during operation. Thanks to these advanced protection systems, freight elevators can prevent unwanted incidents, thereby minimizing risks for both operators and transported goods. The integration of functions such as alarms, phase loss protection systems, and overload control helps maintain stable operating performance and reduces the pressure on technical staff in monitoring and maintenance. These improvements in safety and performance have contributed to improving the service quality of freight elevators , making the equipment reliable and suitable for many harsh industrial environments. Thanks to that, businesses not only achieve high efficiency in transporting goods but also protect assets and people, bringing peace of mind when using.

CLASSIFICATION OF FREIGHT ELEVATORS

Currently, freight elevators are classified in a variety of flexible ways to meet different needs and standards in industrial and commercial fields. Depending on factors such as origin, purpose of use, features and structure, these types of elevators have their own distinct characteristics. In terms of origin, freight elevators can be divided into imported products from countries famous for technology and quality, as well as domestically produced products, providing advantage

.png)

.png)

.png)