The system is processing. Please wait a moment!

- Home experience homelift & elevator technical Sharing experiences

Elevator Machine Room Height Requirements and Notes on Installation

TABLE OF CONTENTS

Requirements for elevator machine room design are increasingly attracting the attention of users and supply and installation units. To ensure that an elevator product can operate and operate stably, compliance with standards is very important. Below, SANKYO Elevator will provide detailed information on common elevator machine room height requirements and how to address them most effectively.

SEE MORE OTHER PRODUCTS:

FACTORS THAT DETERMINE THE HEIGHT OF AN ELEVATOR ROOM

The normal height of each average floor usually ranges from 3000mm to 3300mm. Therefore, to ensure safety during operation, the elevator drum height needs to be designed at least 3500mm. In reality, this drum height will depend on many factors, including:

Load factor or elevator type is one of the important decisions when choosing equipment. On the market today, there are 5 main types of elevators, including: passenger elevators, freight elevators, passenger elevators with goods, food elevators and hospital elevators. The required height characteristics of each type of elevator are specifically described as follows:

For passenger elevators

Passenger elevators are often widely used in high-rise buildings such as apartments, hotels, offices, and multi-storey residential houses. Usually, passenger elevators have common load levels of 600kg, 750kg, 900kg and 1000kg, capable of holding from 9 to 15 people in each trip. The minimum height of passenger elevators is from 4200mm.

Meanwhile, home elevators, among the smallest, have a load capacity of 200kg to 450kg. Therefore, the average height of a home elevator is about 3800mm. For example, a home elevator with a load capacity of 450kg has the following standard dimensions:

- Standard elevator pit size: 1500mm x 1800mm (width x height).

- Standard elevator door size: 700mm x 2100mm (width x height).

- Standard cabin size: 1100mm x 1300mm (width x height).

Clearly, the minimum height of a 450kg home elevator with machine room is 3500mm and 4000mm for type without machine room.

For freight elevators

Freight elevators require high load levels, usually with popular loads such as 500kg, 700kg, 1000kg, 2000kg and 3000kg. This means that the height of the freight elevator will change depending on the load. Below is a table listing some dimensions and OH heights of freight elevators according to each specific load.

|

Weight (kg) |

Height of device (OH) (mm) |

Size of the elevator door (width mm x height mm) |

|

500 |

1400 |

1000 x 2100 |

|

700 |

2100 |

1000 x 2100 |

|

1000, 2000 |

4200 |

1100 x 2100, 1600 x 2100 |

|

3000 |

4000 |

2000 x 2100 |

For food hoists

Food hoists, among the most compact of all elevator designs, have capacities ranging from 50kg to 500kg, and require a minimum OH height of 3000mm. The food elevator door size in this case is 800 x 1000mm (width x height).

For elevators installed in hospitals

Hospital elevators are designed for a specific purpose, serving the movement of hospital beds with large loads, usually from 1000kg, 1350kg, and 1500kg or more. Therefore, the height of hospital elevators compared to other types of elevators is often higher. For hospital elevators without a machine room, the minimum OH height is 4200mm, while for hospital elevators with a machine room, the minimum OH is 4400mm.

In addition, the manufacturer's brand is also one of the factors affecting the height of the elevator. Elevator size and height standards often vary depending on the manufacturer. However, the most important thing is to determine the specific uses that customers want the elevator to serve. Each manufacturer will focus on creating elevator equipment with the most suitable parameters to properly meet the specific needs of customers.

We understand that each project and elevator space is special, so we are always willing to advise and design the most optimal elevator solution for our customers. Our team of experts not only has in-depth knowledge of technical standards but also focuses on listening and understanding each customer's specific wishes to ensure that the final product will completely satisfy and surpass expectations.

SEE MORE OTHER PRODUCTS:

DRAW UP DETAILED DESIGNS FOR ELEVATOR ROOM

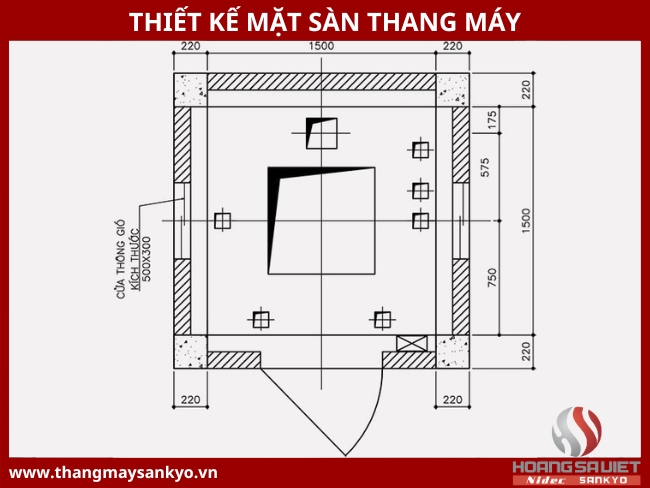

Elevator floor design

During the floor design process, attention should be paid to ensuring the appropriate thickness of the engine room floor, just enough without adding unnecessary weight. The elevator machine room is not the main bearing area during elevator operation. The standard floor of a machine room is usually about 120mm thick, designed to ensure performance without affecting the elevator's ability to operate.

Design technical holes

Some basic information about technical holes in the engine room floor is as follows:

-

Hole 200mm x 200mm: This is the location used to thread the elevator cable.

-

Hole 100mm x 100mm: Includes 6 holes, including 2 holes for connecting cables to control over speed, 2 holes for installing light wires of the elevator door, and 2 holes for installing rails leading to the cabin.

-

Hole 700mm x 700mm: This is a technical hole used to thread the hoist hook to support the elevator installation process. In addition, this is also the location to bring tractors and electrical cabinets to the elevator machine room. Most importantly, this hole also plays an important role in routing the cable to the top of the cabin, so make sure to cover these holes when completing the installation.

-

With 100mm x 100mm technical holes , you can decide to install front or rear. If not available, drilling and cutting may be considered during installation. Therefore, the thickness of the floor should also be maintained at about 120mm for convenience during the drilling and cutting process.

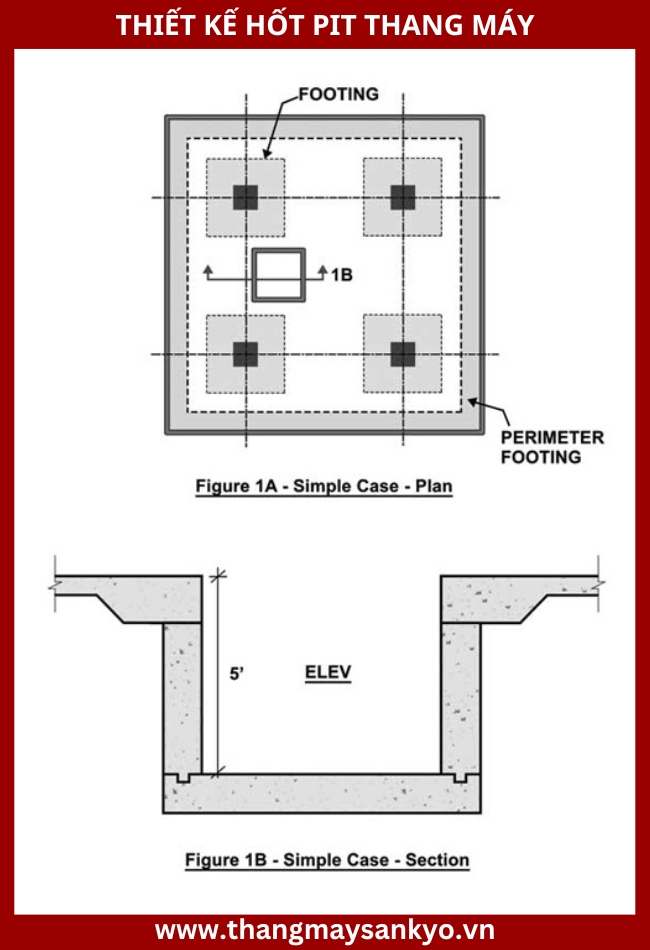

Design of elevator PIT pit

The PIT hole is measured from the floor of the first floor to the bottom of the elevator pit. Each type of elevator will have its own type of PIT pit, depending on the size and depth of the elevator. Therefore, to ensure proper construction of the PIT pit, a few important things need to be noted.

Ensure the design has the correct size, height, width and depth as required. If there is excess area, it should be made wider and deeper than the minimum parameters to create comfort during the installation and operation of the elevator. Most importantly, it should not be narrower or shallower than the minimum parameters, to avoid dangerous situations during future elevator operation.

When installing and designing a PIT pit, attention should be paid to waterproofing the pit. No electricity or water pipes are allowed to enter the PIT pit area. Regarding minimum thickness, the PIT pit needs to be at least 150mm thick to ensure the safety and stability of the elevator system.

SEE MORE OTHER PRODUCTS:

ELEVATOR SPEED REQUIREMENTS

Regarding elevator speed, it is important to calculate and understand the exact number to make appropriate decisions when installing. Elevator speed often depends on the number of floors of the building, with a quick calculation being to multiply the number of floors by 10 to achieve the exact or closest speed.

Note that elevators often have variable speeds at each stage of transportation, but have equipment that ensures smooth and stable operation. This small variation is nothing to worry about, and the installation process will ensure the elevator's efficient operating speed.

PURPOSE OF THE HEIGHT OF THE ELEVATOR

As mentioned earlier, the height of the elevator plays an important role in the manufacturing and installation process. The height requirements of this equipment have a major impact on elevator performance and safety. Here are the specific benefits of paying attention to this height:

-

Ensuring safety: High enough height ensures safety during elevator operation, keeps the equipment operating stably and avoids problems when moving between floors.

-

Convenience for installation: Reasonable calculation of Overhead height (OH) helps facilitate the installation of equipment at both ends of the elevator. OH needs to be adjusted to suit the height of the machine room and other equipment for the elevator to operate effectively.

-

Convenience for maintenance: Appropriate height creates comfortable and convenient working conditions for elevator repair, maintenance and service workers.

-

Customization for each project: Ensure that each elevator device is customized to suit each specific project, not only ensuring comfort but also demonstrating the high aesthetic value of the elevator system . machine.

REPUTABLE QUALITY ELEVATOR INSTALLATION AND MAINTENANCE UNIT - HOANG SA VIET SANKYO

SANKYO Elevator is a reputable and trusted elevator installation unit in the elevator industry. Dedication and quality are the top goals of SANKYO Elevator. A team of highly qualified technicians with extensive training ensures that home elevator installation is performed accurately and safely.

We are committed to meeting schedules and ensuring that our products and services fully meet quality and safety standards. At the same time, we constantly strive to improve service quality and apply the latest technology to meet the increasingly diverse and complex needs of customers. Customer satisfaction and peace of mind is the greatest source of encouragement for us to constantly innovate and develop.

“Hoang Sa Viet Elevator - Always with you on every high floor!”

HOANG SA VIET ELEVATOR - LEADING PRESTIGIOUS ELEVATOR COMPANY IN VIETNAM

Consulting Specialist: 0942.222.075 Head Office: 184/20 Le Dinh Can, Tan Tao Ward, City. HCM Hanoi headquarters: No. 229, D. Van Tri, Van Noi, Dong Anh, Hanoi Website:

thangmaysankyo.vn Email: hungpham@hoangsaviet.com

.png)

.png)

.png)